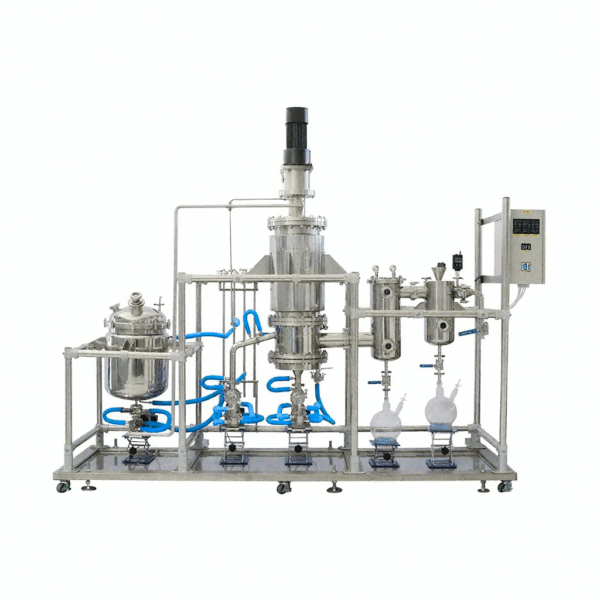

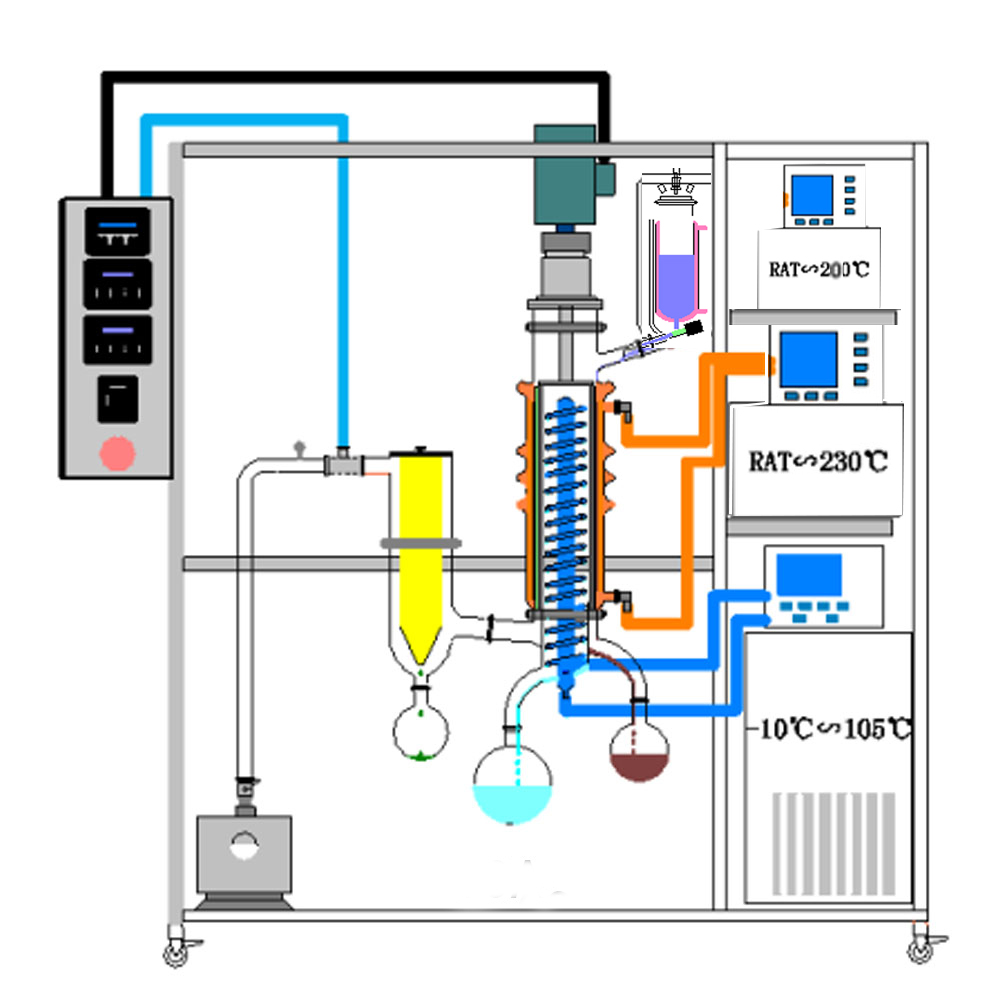

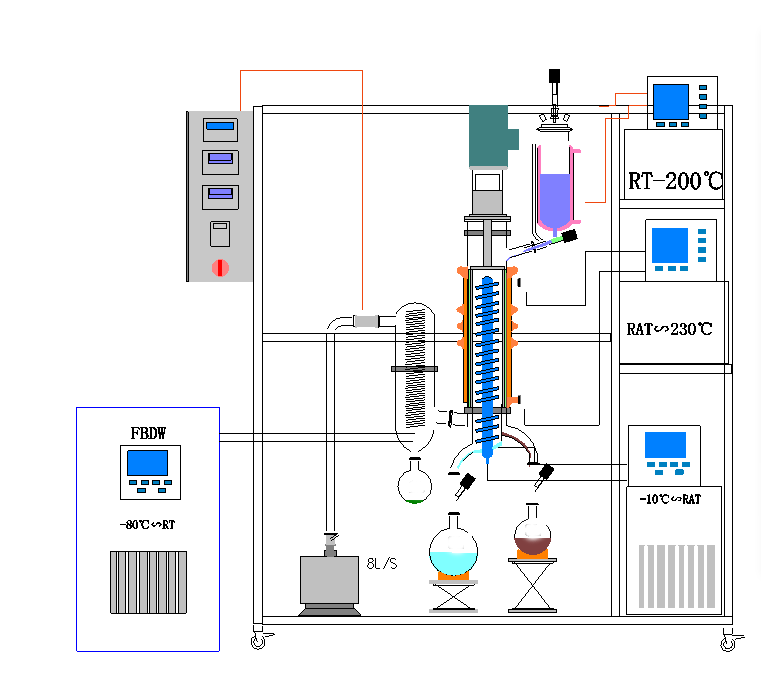

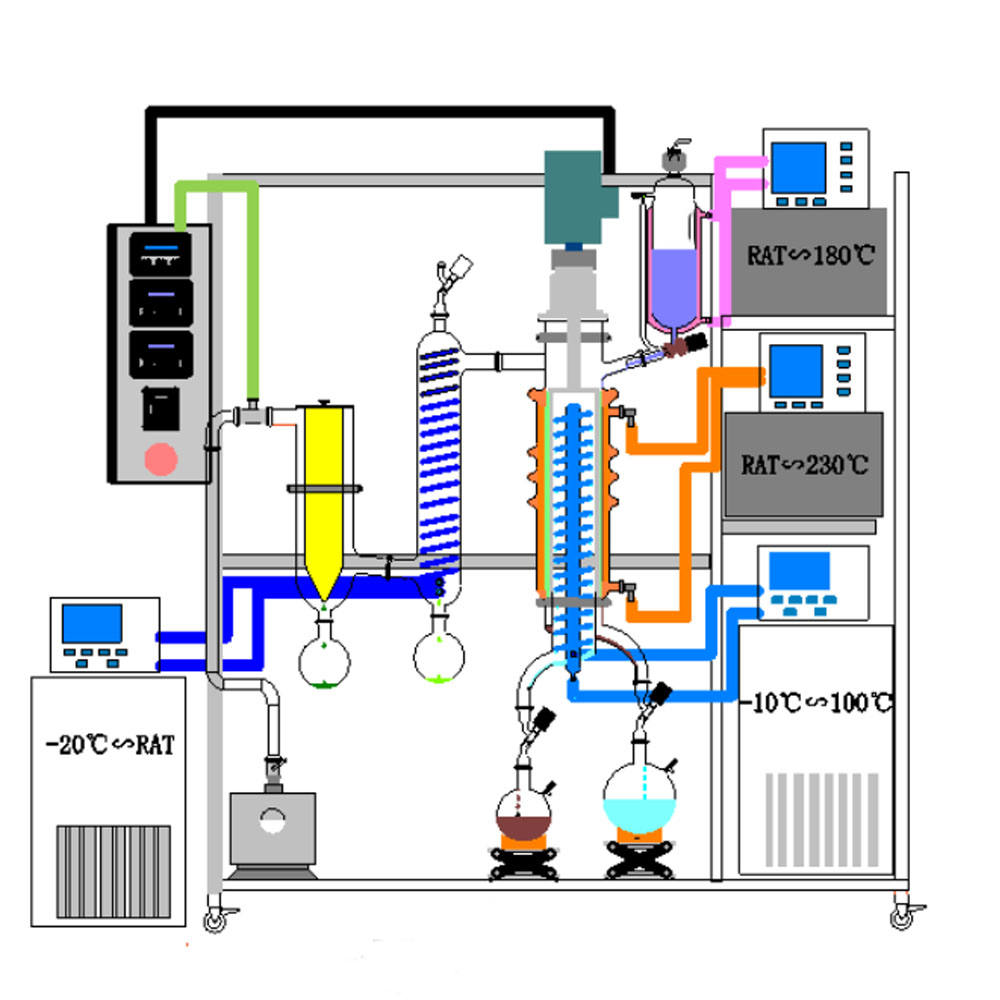

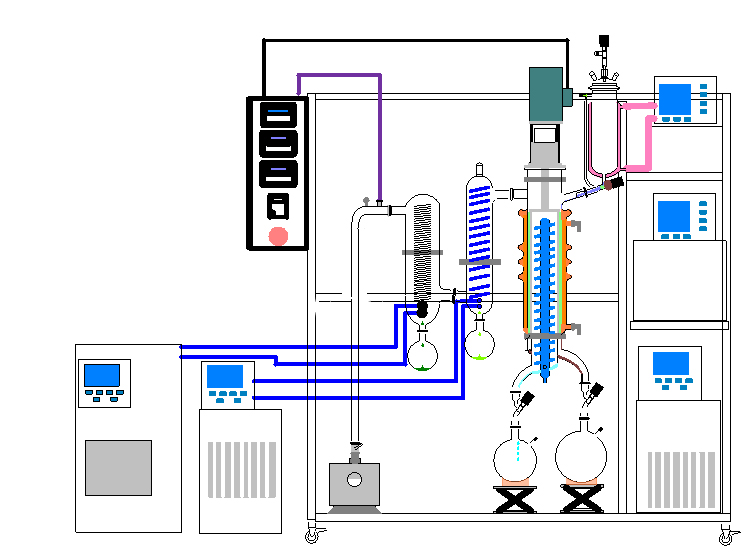

·The glass parts are made of high borosilicate 3.3 material, with excellent visibility.

.The magnetic coupling seal can maintain a higher vacuum degree to ensure the evaporation effect.

·Scraper film forming design, contact material material stainless steel 316L+PTFE.

.The sealing ring is made of fluorine rubber or tetrafluoroethylene, suitable for diferent material applications.

·The main evaporator can be designed with full jacket and full insulation to ensure material fluidity.

·Digital display Pirani vacuum gauge, accurate feedback of vacuum degree.

·Multi-plan structure configuration

| Model | WFE-60G | WFE-80G | WFE-100G | WFE-150G | WFE-200G |

| Feeding rate(L/h) | 0.05-2 | 0.05-3 | 0.1-5 | 0.2-10 | 0.5-15 |

| Effective evaporation area(m²) | 0.06 | 0.1 | 0.15 | 0.25 | 0.35 |

| Feeding flask volume(L) | 0.5 | 2 | 3 | ||

| Distillate receiving flask(L) | 0.5 | 2 | 5 | ||

| Residue receiving flask(L) | 0.5 | 1 | 2 | 5 | |

| Rotation speed(rpm) | 50~460 | ||||

| Vaccum level(mbar) | ≤0.001 | ||||

| Operation temperature(℃) | ≤300 | ||||

| Power supply | 220V/50Hz,1P (380V/480V 3P) | ||||

| Dimensions(mm) | 1700*610*1700 | 1900*610*1800 | 1900*610*1900 | 2100*610*2300 | 2250*610*2400 |